Build with the best

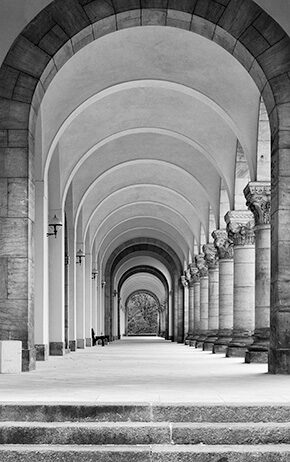

Precast concrete sets the standard in construction.

When you build, you have choices. Precast concrete has many advantages over other construction materials. Click below to compare precast to other resources.

Precast vs. Wood

Precast is:

Concrete becomes stronger over time. Structures like the Pantheon are still standing thousands of years later.

Concrete supports more weight and withstands greater pressure. It is impervious to mold and mildew.

Wood is:

Wood burns at 392 degrees Fahrenheit.

Wood is less dense and more susceptible to the effects of fire, water and infestation.

Wood is prone to mold and mildew that are hazardous to your health.

Precast vs. Plastic

Precast is:

Modern-day precast concrete has a service life in excess of 100 years and is easily recycled for reuse by crushing.

Concrete can withstand forces from 2,500 to 10,000 pounds per square inch and once cured holds its shape very well.

Plastic is:

Polyethylene and other plastics used in construction have melting points ranging from 230 F to 689 F.

The wide variety of industrial polymers and the use of additives increases the complexity – and the cost – of the recycling process.

Polymers and other plastics create microplastics that are polluting our water, food and air as they degrade. Burning plastics releases toxic chemicals.

Precast vs. Steel

Precast is:

Precast concrete is often used to protect steel against corrosion.

Precast concrete is made locally, reducing time and energy needed for transport to job site.

Concrete can tolerate up to four hours of intense heat before it begins to break down.

Steel is:

Steel usually travels a significant distance from where it’s made, adding time and energy costs.

Steel requires additional insulation barriers to raise fire resistance and meet fire codes.

Precast vs. Aluminum

Precast is:

Precast concrete is made locally, reducing time and energy needed for transport to job site.

Concrete can withstand nearly nearly 2x the heat that aluminum can.

Aluminum is:

Aluminum has a melting point of 1382 F, well below the 1500 F of a typical house fire.

Which of the following iconic landmarks around the world include precast concrete?

From ancient to very modern, all four of these structures include precast concrete.

How much of a concrete building can be recycled?

Almost 100% of a concrete building can be recycled, no matter how heavily reinforced. Precast concrete products also eliminate waste disposal of excess building materials like site-built wood forms, conserving space in landfills.

Some precast concrete power poles can withstand winds up to …

Precast concrete power poles can weigh about 8,000 pounds and won’t snap in half in the face of strong hurricane winds. With a wind rating of 145 mph, some poles could withstand up to a strong Category 4 hurricane.

Compare the benefits

Precast concrete is the ideal choice for safe, durable and eco-friendly construction.

Precast concrete can reduce construction time by up to one-third.

The typical lifespan of precast concrete products, dependent on environmental conditions.

Amount of sound energy reflected by a concrete surface, providing excellent sound reduction.

Connect with a precaster

Search your state and surrounding area for precast manufacturers who are ready to meet your tight deadlines, customize products to suit your project and deliver durability and resilience.